Innovations

01

Maximised Safety and Reliability

Users benefit from a comprehensive safety setup that monitors all critical operational parameters, ensuring safe transport of goods. The advanced safety systems help prevent breakdowns, thereby protecting both operators and cargo.

Users benefit from a comprehensive safety setup that monitors all critical operational parameters, ensuring safe transport of goods. The advanced safety systems help prevent breakdowns, thereby protecting both operators and cargo.

02

Enhanced Operational Flexibility

Adjustable speed and smooth acceleration/deceleration allow the lift to handle different load weights and travel heights efficiently. The precision control over start-stop functionality protects cargo from impact damage, ensuring safer transportation.

Adjustable speed and smooth acceleration/deceleration allow the lift to handle different load weights and travel heights efficiently. The precision control over start-stop functionality protects cargo from impact damage, ensuring safer transportation.

03

Resilience in Emergency Situations

Electronic and manual options ensure continued operational control and security in emergency scenarios.

Electronic and manual options ensure continued operational control and security in emergency scenarios.

04

Reduced Maintenance and Operational Costs

With remote diagnostics and data collection, maintenance requirements are lower, and fewer on-site visits are necessary. This translates to minimised maintenance costs and prolonged service life.

With remote diagnostics and data collection, maintenance requirements are lower, and fewer on-site visits are necessary. This translates to minimised maintenance costs and prolonged service life.

05

Quiet and Energy-Efficient Performance

Eco-friendly components, such as the screw pump and submersible motor, lead to quieter operation and reduced energy consumption, helping businesses cut down on energy costs and achieve their sustainability goals.

Eco-friendly components, such as the screw pump and submersible motor, lead to quieter operation and reduced energy consumption, helping businesses cut down on energy costs and achieve their sustainability goals.

06

Data Collection for Performance Analysis

The lift's remote monitoring system also records data on trip frequency, usage intensity by time of day, and fault occurrences. This data allows facilities to analyse lift usage patterns, plan maintenance schedules, and optimise lift operations to meet changing demand. By providing insights into equipment performance, the HS model enables businesses to make data-driven decisions that improve efficiency and extend the life of the lift.

The lift's remote monitoring system also records data on trip frequency, usage intensity by time of day, and fault occurrences. This data allows facilities to analyse lift usage patterns, plan maintenance schedules, and optimise lift operations to meet changing demand. By providing insights into equipment performance, the HS model enables businesses to make data-driven decisions that improve efficiency and extend the life of the lift.

07

Flexible Configuration and Control Options

Real-time monitoring with adjustable stop levels and the option for remote adjustments provide greater operational flexibility, allowing users to optimise lift performance based on specific workflow requirements.

Real-time monitoring with adjustable stop levels and the option for remote adjustments provide greater operational flexibility, allowing users to optimise lift performance based on specific workflow requirements.

Standard and Optional Features for Enhanced Lift Performance

Our comprehensive range of standard and optional features allows you to customise your lift system to meet specific operational requirements. From door automation options to safety mechanisms and passenger interfaces, these carefully designed components work together to improve accessibility, safety and user experience whilst maintaining operational efficiency.

01

Semi-automatic doors

Doors which close automatically, but must be manually opened, single or two leaf options available

Doors which close automatically, but must be manually opened, single or two leaf options available

02

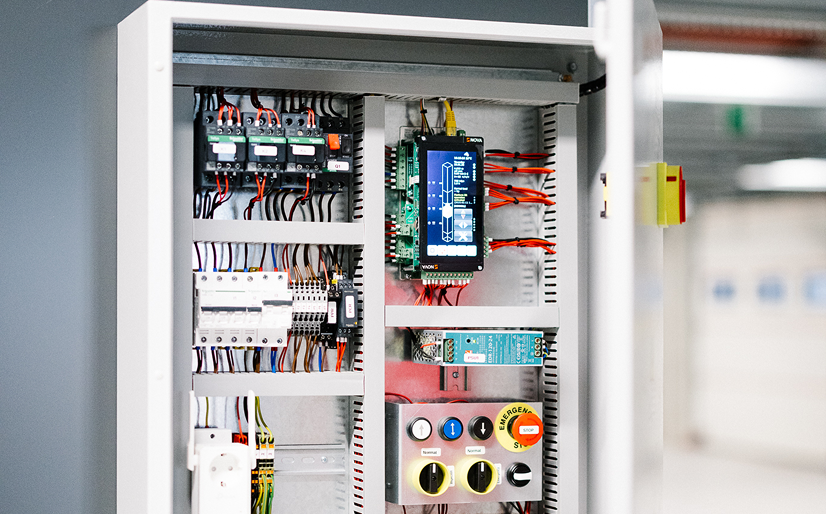

Two-in-one power unit and control panel compartment

Eliminates the need for a dedicated machine room

Eliminates the need for a dedicated machine room

03

Oil heater

A system designed to heat hydraulic oil in low ambient temperatures to maintain hydraulic properties of the oil

A system designed to heat hydraulic oil in low ambient temperatures to maintain hydraulic properties of the oil

04

Landing operating panel display

A screen that shows basic information about the position of the car on the car operating panel

A screen that shows basic information about the position of the car on the car operating panel

05

Car operating panel display

A screen that shows basic information about the position of the car on the landing operating panel

A screen that shows basic information about the position of the car on the landing operating panel

06

Fan

A fan that keeps air circulating in a fully enclosed car

A fan that keeps air circulating in a fully enclosed car

07

Non-standard push

buttons

Different push buttons to suit the needs of the user (operation in heavy gloves, etc.)

Different push buttons to suit the needs of the user (operation in heavy gloves, etc.)

08

Additional car operating

panel

Another car operating panel on the car to enable access in case the other one is blocked by cargo

Another car operating panel on the car to enable access in case the other one is blocked by cargo

09

Electromechanical anti-drift lock display

Mechanically prevents the platform from lowering as the car is being loaded

Mechanically prevents the platform from lowering as the car is being loaded

Hydraulic cargo lift hs1

Hydraulic cargo lift HS2