Customised

Doors

Choosing the right door configuration is crucial for operational efficiency and safety in industrial lift applications. The material, type, and opening mechanism can impact energy use and ease of access, making it essential to match the door design to your facility’s workflow and compliance needs.

Hinged

b) Panoramic

c) Fire resistant

b) Panoramic

c) Fire resistant

b) Made of galvanised steel

c) Made of stainless steel

Walls & Floors

Wall and floor material selection affects not only the cabin’s durability and hygiene but also its resistance to impact, corrosion, and wear. Factors like operational environment, maintenance expectations, and aesthetic preferences all play a role in determining the most suitable solution. Materials must balance safety, load-bearing capacity, and cleaning requirements. The right flooring helps prevent slippage, supports heavy use, and can reduce long-term maintenance, especially in sectors with specific hygiene or durability standards.

Metal

steel

steel

b) Sanded

c) Plain

b) Made of stainless steel

b) Chequered AISI 304

c) Chequered AISI 316

d) Striped metal sheet

(Multiple texture and colour options available)

b) Dot

c) Foot

d) Combi

Do you have

questions?

Do you have

questions?

CEILINGS

Ceiling design influences lighting, ventilation, and compliance to hygiene protocols. Selecting the appropriate structure ensures optimal performance, particularly in environments with temperature control or air quality considerations.

requests

b) Sanded

c) Plain

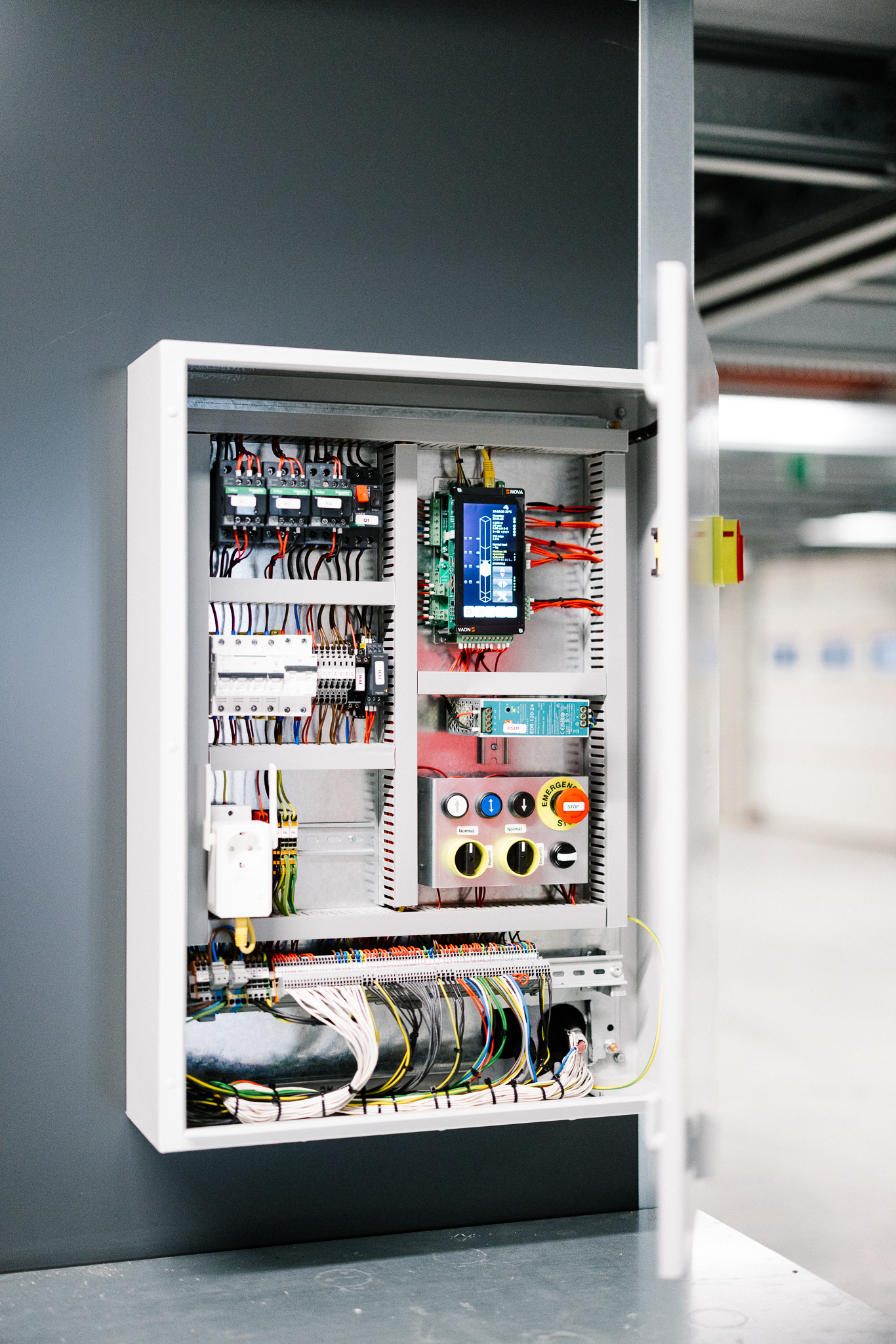

Push buttons

Pushbutton selection directly impacts user experience, durability, and operational reliability of industrial lifts. Factors such as usage frequency, exposure to dust or moisture, and required accessibility features should guide the choice. Choosing the right interface enhances safety, reduces downtime, and ensures compliance with user and industry standards.

b) Bicolour

b) Bicolour

Hydraulic cargo lift hs1

Hydraulic cargo lift HS2