How a Custom Lifting Solution Solved

a Client’s Case (An HS2 Case Study)

In the world of industrial equipment, standard, off-the-shelf solutions are often just a starting point. Every business, every building, and every production process presents unique challenges that demand flexibility and a bespoke approach. This is why the foundation of a successful partnership is built not only on engineering expertise, but also on a commitment to truly listen to the client.

In this post, we want to share a success story – a project that perfectly illustrates our approach to our work. This is the case of a custom-configured HS2 hydraulic cargo lift, which we designed and installed for a client here in Lithuania.

It Begins with Listening: The Foundation of Our Partnership

Our extensive experience has taught us a fundamental truth about successful collaboration: to deliver the best solution, you must first understand the situation. That is why we begin every project with in-depth consultations. We dedicate time not only to discuss technical parameters but also to gain a deep understanding of the client’s operational specifics, their expectations, and the environment where the equipment will function. Only after meticulously defining the requirements can we proceed to engineer a solution.

Platform size: up to 4 m x 3 m.

Load capacity: up to 3 tonnes.

Minimum pit depth: 400 mm.

Travel height: up to 12 m.

The Challenge: Defining a Clear Set of Requirements

Following our consultations with the client, we outlined a clear set of requirements for the future lift. The equipment had to:

- Meet specific performance metrics: It needed to handle a designated load capacity to ensure a smooth workflow.

- Offer long-term durability and reliability: It had to be built to withstand intensive daily use without downtime.

- Seamlessly integrate with the existing space: The lift’s design had to be adapted to the building’s layout and structural characteristics.

Our task was not simply to sell a product, but to engineer a solution that met every one of these criteria.

The Solution: The Paradis Cargo HS2 – Power and Flexibility

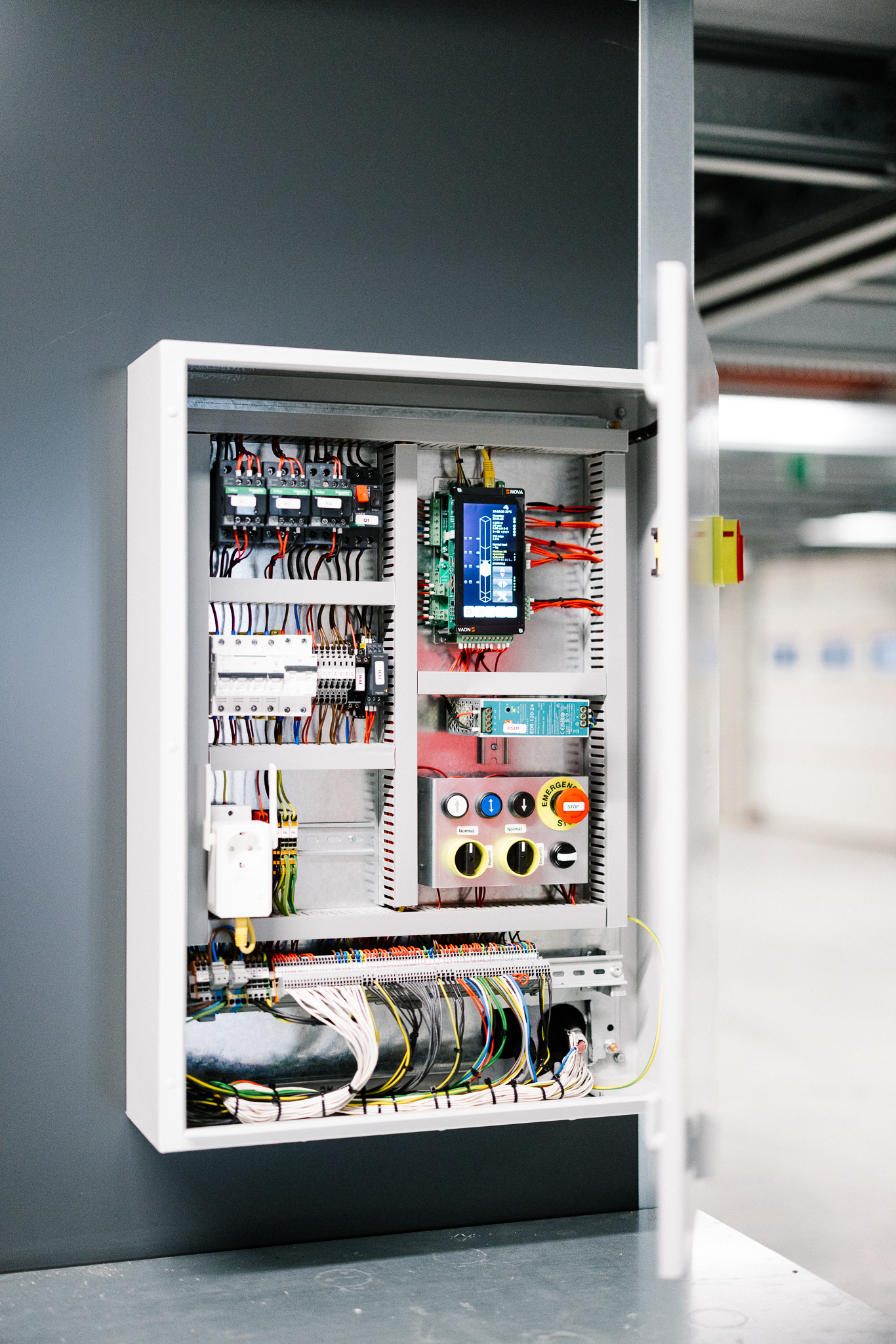

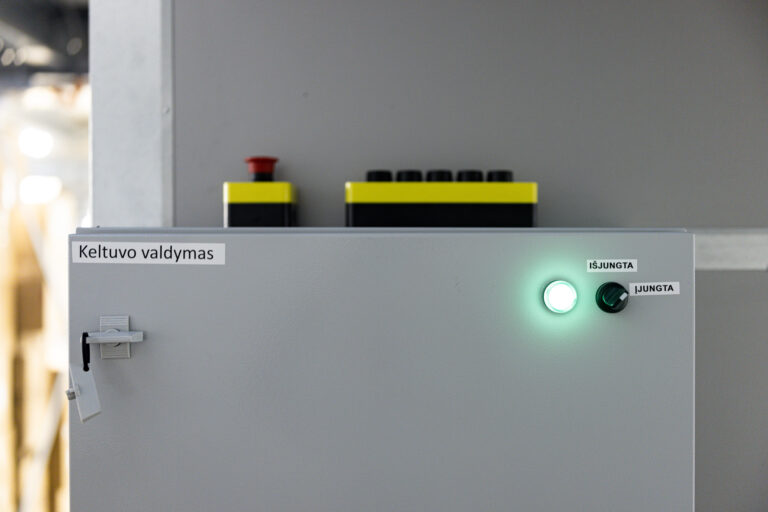

Considering the defined requirements, we proposed the optimal solution: the flagship of our Cargo lifts line, the Paradis Cargo HS2. This model, which you can see in the accompanying photos, is designed for heavy loads and intensive use.

The HS2 is the most powerful in our cargo series, capable of lifting up to 3,000 kg, with a platform size of up to 4×3 meters. It was the flexibility of this model that allowed us to configure it precisely to the client’s needs.

In this specific application, the lift is used for transporting pallets with finished goods from the production floor to the second-floor warehouse.

Our Standard: Quality Without Compromise

Every project, whether it’s implemented in Lithuania or on the other side of the world, reflects our commitment to quality. The HS2 model is characterised by its quiet and smooth-operating mechanical components, which ensure not only comfort but also exceptional longevity. Its reinforced car panels are prepared to withstand the rigours of real-world industrial conditions and accidental impacts, protecting both the cargo and the equipment itself.

This project is a prime example of how we combine European manufacturing standards with custom-tailored solutions to deliver maximum efficiency, safety, and reliability.

Looking for a Custom Solution? Let’s Talk.

If you are facing a challenge that requires a reliable and bespoke cargo lifting solution, we invite you to get in touch with us for a consultation.

➡️ Are you looking for a manufacturing partner in Europe capable of delivering high-quality, tailor-made hydraulic solutions? Contact us to discuss a potential partnership.

Want to learn more about HS2 or other lifts from the Paradis Cargo line? Get in touch with our team today!