Cargo Lift Controllers that

Enhance Service Speed

Reading time: 4 min

Cargo Lift Controllers that Enhance Service Speed

Time is money, especially in the lift industry

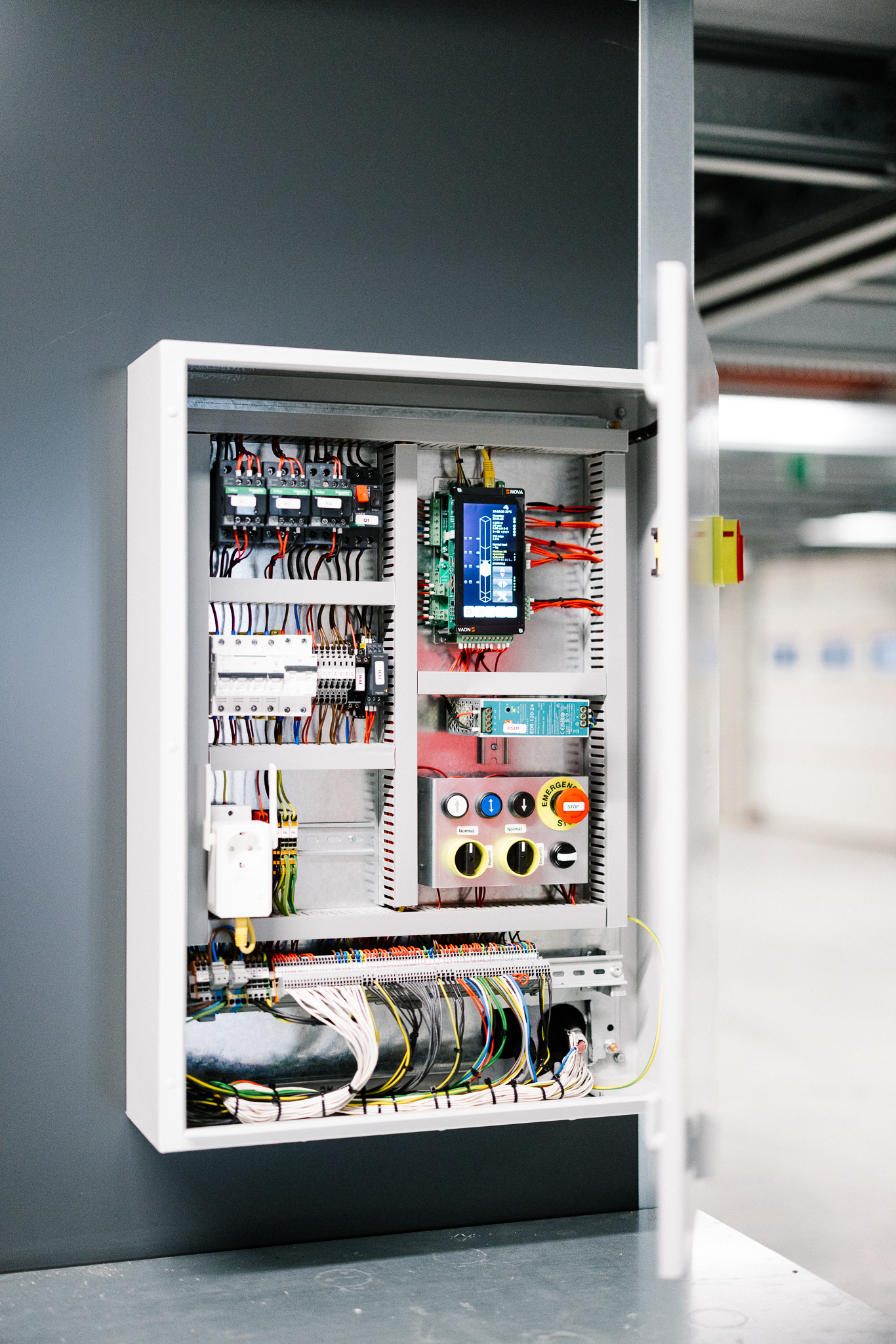

Whether you are in the installation phase or performing routine maintenance, every minute counts. At Paradis Lifts, we believe that cargo lift controllers should be an asset, not an obstacle, for every technician. When designing our HS Model Hydraulic Freight Elevators, we prioritized smart technology to meet the unique requirements of modern operations. The result is a system engineered for flexibility and high performance, featuring a smart controller that turns complex tasks into routine procedures.

Here are 6 ways our smart controller functionality reduces commissioning time and simplifies compliance for service providers:

1. Dedicated Assembly/Installation mode

The initial setup of a freight lift can be the most time-consuming phase. Our controller features a specific Assembly – Installation Operation Mode.

- How it works: This mode allows the lift to behave differently from normal operation specifically to facilitate the installation process.

- The Benefit: It simplifies precise lift maneuvering during construction, allowing installers to focus on the mechanics rather than fighting the software.

2. Automated Testing Assistants

Safety checks are non-negotiable, but they don’t have to be tedious. We have integrated automated testing assistants directly into the vargo lift controller to remove the guesswork:

- UCM-Testing: Allows for the simulation of an Unintended Car Movement (UCM) event to ensure safety protocols are active.

- Overload Indication: The system allows you to simulate an overload event to verify that the buzzer and display are fully functional without needing to physically load the car with test weights.

- Safety Circuit Bridge: A testing assistant that allows for the simulation of safety circuit bridge events.

3. Runtime Supervision

Verifying operational limits is crucial for certification. Our Runtime Supervision Testing feature allows technicians to simulate runtime limiter activation events. This provides quick confirmation that the cargo lift is operating within its safe limits and adheres to the Enhanced Safety System protocols. This project is a prime example of how we combine European manufacturing standards with custom-tailored solutions to deliver maximum efficiency, safety, and reliability.

4. Service Trip Operation

Routine maintenance often requires checking the shaft while the car is stationary. Our Service Trip/Position Operation allows maintenance workers to quickly check if the car is occupied and then send it to a designated service landing. This feature enables safe maintenance work in the shaft while the car remains stationary at a specific level, improving safety for the technician.

5. Remote Diagnostics and Troubleshooting

One of the biggest “time thieves” in service is driving to a site just to diagnose a minor error. The Paradis HS1 and HS2 cargo lift models are equipped with Remote Monitoring & Diagnostics.

- Real-Time Data: The system provides live monitoring of speed, positioning, and safety elements.

- Remote Reset: It enables remote troubleshooting and the resetting of errors, significantly reducing the need for on-site maintenance visits.

6. Data-Driven Maintenance Intervals

Instead of relying on arbitrary dates for maintenance, our controller utilizes actual usage data. The system collects operational data, such as trip frequency and problem history, to optimize maintenance schedules.

- Smart Alerts: The Maintenance Intervals function allows for automatic warnings or the disabling of the lift after a designated number of trips or a set time has passed.

- The Benefit: This leads to minimized maintenance costs and a prolonged service life for the equipment.

- Real-Time Data: The system provides live monitoring of speed, positioning, and safety elements.

- Remote Reset: It enables remote troubleshooting and the resetting of errors, significantly reducing the need for on-site maintenance visits.

The bottom line: Efficiency and Safety go hand-in-hand

From the HS1 to the heavy-duty HS2 cargo lifts, our elevators are designed to lift smarter. By combining robust hardware with intelligent software, we help service providers cut down on commissioning time while ensuring the highest standards of safety.

Ready to upgrade your workflow?

To learn more about our smart controllers and custom cargo lift solutions, check our cargo catalogue, social media page, contact us via email or simply fill out the message form below.